Source: http://personaldiecutting.com/silhouette-curio-vs-cameo/

Wondering what is the difference between the

Silhouette Curio and

Silhouette Cameo? Today, we will be comparing the Curio and Cameo machines and covering the differences between them.

What is the Silhouette Curio?

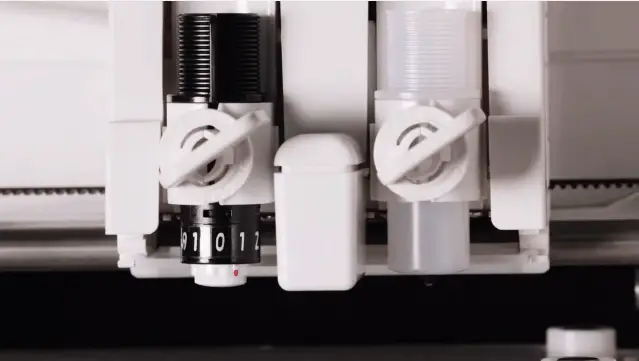

The Silhouette Curio is one of Silhouette’s newest craft machines for DIY projects that is loaded with features. The Curio has more capabilities than the Silhouette Cameo. The Curio can not only cut and draw, but also emboss, score, sketch, stipple, and etch. With dual carriages, you can mix and match functions.

Although the Silhouette Curio is more versatile than the Silhouette Cameo cutting machine, the Curio is not meant to be a replacement for the Cameo, but rather a supplement, or companion tool. The Silhouette Cameo has a 12 inch wide cutting width, and cut cut up to 10 feet long. The Curio machine, is limited to a 8.5 inch by 12 inch cutting surface.

What can the Curio do that the Cameo machine can’t?

Here is a list of capabilities that the Curio can do, but the Cameo can’t:

- Metal and foil stippling

- Metal etching

- Dual carriage multitasking (multiple tasks in one pass)

- Embossing

- Score & Emboss

- Print & Emboss

- Deep-cut capabilities* (leather, foils, foams, and more)

- Using thicker materials as project surfaces (example: stencils sketched directly onto wood up to 5mm thick)

*To cut materials like leather and foam, you’ll need to use the deep cut blade.

The Currio comes with dual carriage heads, so you can mix and match tools. For example, you could print and cut, or print and emboss, or even use two

different colored pens.

What can the Cameo do that the Curio machine can’t?

The Cameo machine is better for cutting. The cutting width of the Cameo is 12 inches, and it can cut up to 10 feet long without a mat. This is great if you are making large banners or home decor.

The Cameo also has an on board touch screen, where you can load and cut designs without a computer using a USB drive. This is handy if you are traveling with the machine and won’t have access to a computer.

Silhouette Curio vs Silhouette Cameo Comparison

Here is a side by side comparison for the Silhouette Curio and Silhouette Cameo. Most differences are with the capabilities and cutting width.

| | Silhouette Cameo | Silhouette Curio |

|---|

|  |  |

| Cut | Yes | Yes |

| Draw | Yes | Yes |

| Emboss | No | Yes |

| Etch | No | Yes |

| Score | No | Yes |

| Stipple | No | Yes |

| PixScan Technology | Yes | Yes |

| Cutting Force | 210 grams | 210 grams |

| Cutting Size | 12 inches by 10 feet | 8.5 inches by 12 inches |

| MSRP | $299.99 | $249.99 |

|

|

|

The accessory tools for the Curio do fit inside the Cameo, and may work, but the official word from Silhouette is that it’s not recommended.

Both the Curio and Cameo will be using the same type of software, but the Curio will have more option unlocked for capabilities such as embossing and etching.

What kinds of materials can be used?

Anything type of material that the Cameo can die cut, the Curio can cut, even fabric materials. However, the Curio can use materials as much as 5mm thick, and cut materials such as foam and leather, which will require a deep cut blade

Curio Etching

The Curio can etch onto soft metal surfaces, such as aluminum, copper, and brass.

Curio Embossing and Scoring

The Silhouette Studio designer is optimized to emboss and score on paper products. With some experimentation however, you could try embossing on soft/think metals.

Overall Differences

The main difference between the

Silhouette Curio and

Cameo are the capabilities and size. The Curio is designed to have more variety when it comes to capabilities, like embossing and etching, but the Cameo with its 12 inch cutting width is best for cutting materials.

The Silhouette Curio™ hobby machine is the perfect complement to Silhouette's other cutting tools, the Silhouette Portrait® and Silhouette CAMEO®. Simply connect the Curio to your PC or Mac with the included USB cable and use the included software, Silhouette Studio®, to design your project. Then send your project to the Curio to put your signature style on countless DIY projects. Curio is the perfect machine for DIYers that love to diversify their creativity. With Curio you can:

• Create beautifully etched metal (stippling/etching tool sold separately)

• Embellish foils and metals with unique stipple patterns (stippling/etching tool sold separately)

• Sketch intricate, multi-color designs

• Create one-of-a-kind stippled ink projects (sketch pens and felt tip pens sold separately)

• Cut custom designs out of paper, card stock, vellum, vinyl, fabric, stencil material and more

• Cut or sketch fonts already installed on your computer

• Add embossing or debossing textures to soft papers, vellum and other delicate materials

• Use unique materials as project surfaces such as woods, canvas, metals, and more

• Register and cut printed materials (Print & Cut feature)

Curio is driven by powerful Silhouette Studio® software as well as the Silhouette Design Store, a marketplace of over 70,000 ready-made designs available for purchase. Find the perfect design, resize and customize the design for your project, or design your own from scratch using hundreds of design tools in the powerful Silhouette Studio® software.

The Curio is the only machine that can unlock the stippling, etching, debossing, embossing and dual carriage features in Silhouette Studio® design software.

===========================================================